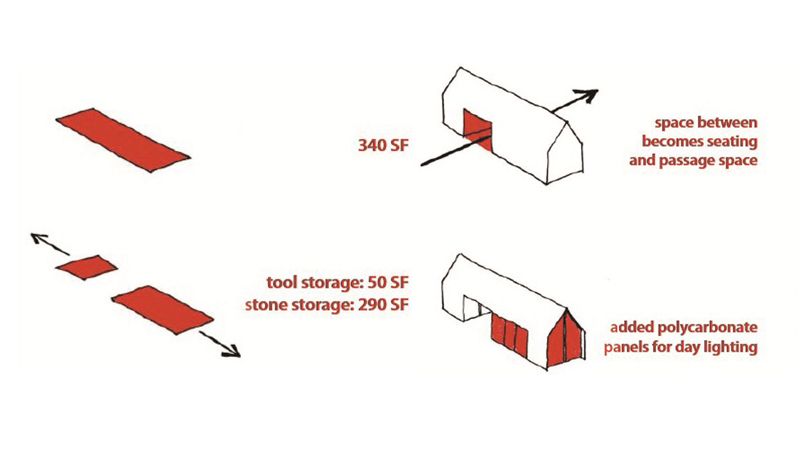

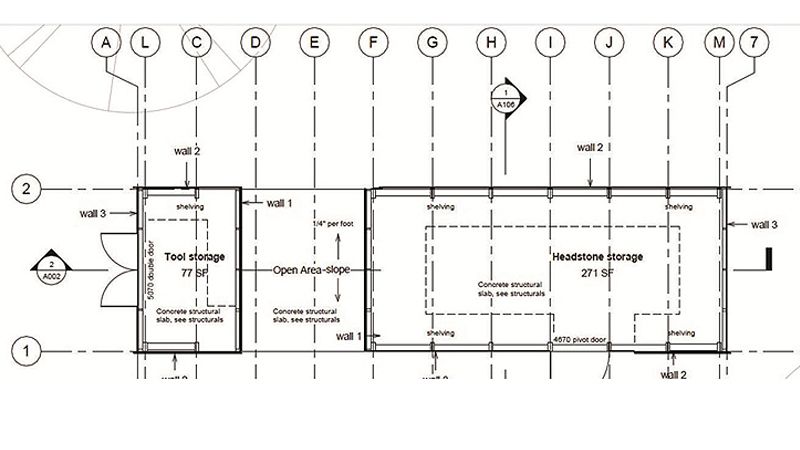

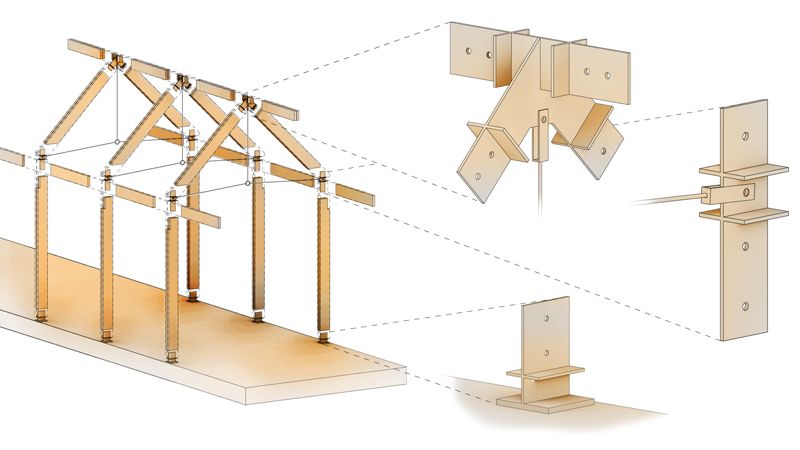

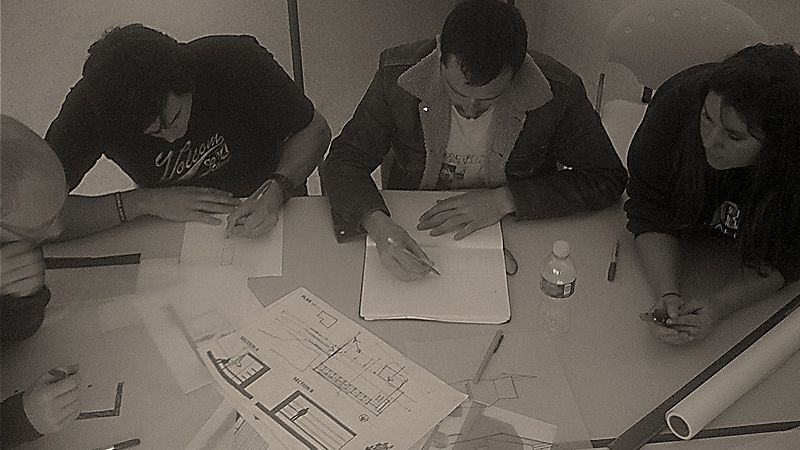

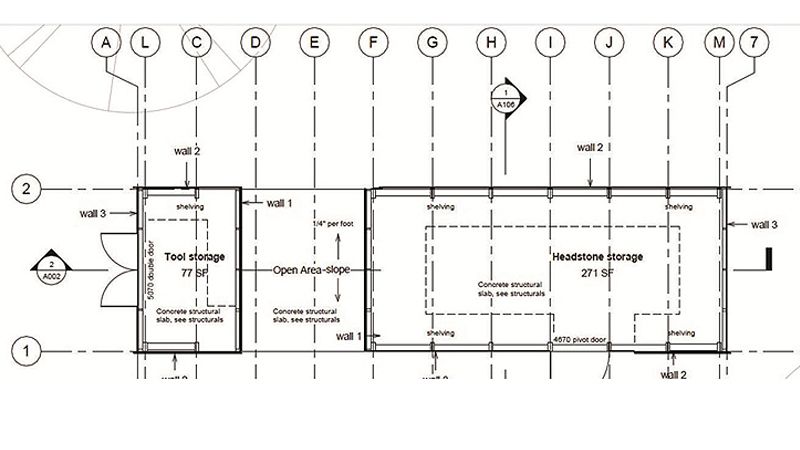

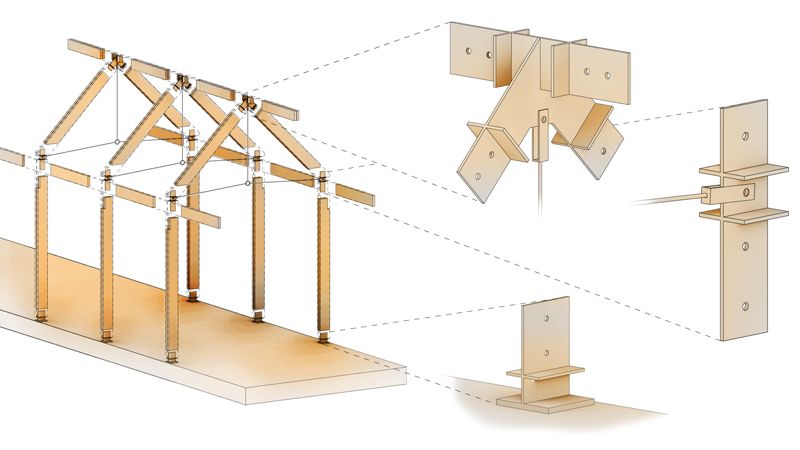

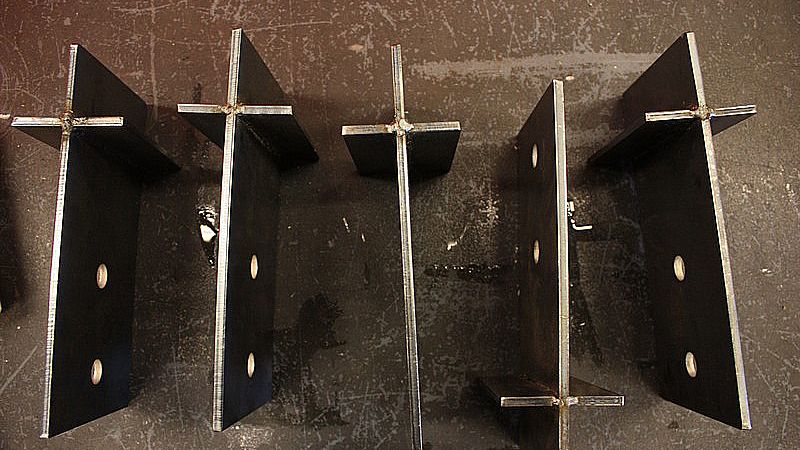

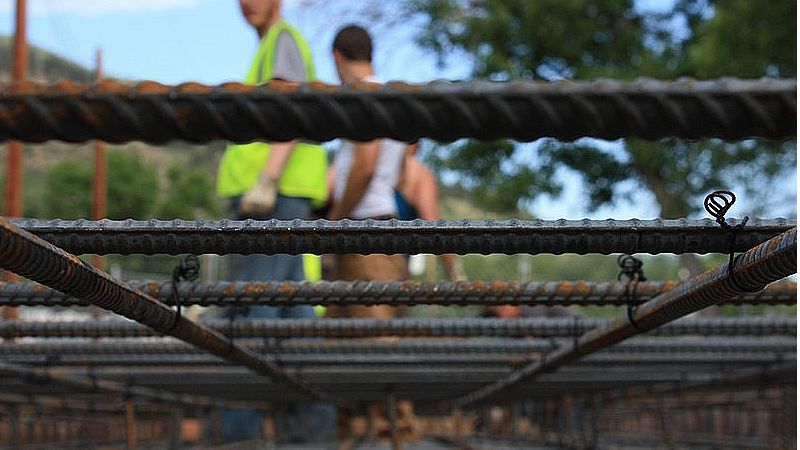

Process Some of the current trends in design thinking were put forward to the students where we used mime maps, sticky notes, discussion, quick charettes and prototyping so that students could respond to the ideas of death, life, historic context, timelessness, program, sense of place etc…  Process Students are working in teams and in a highly collaborative way to design different ideas and schemes for the landmarks board meetings.  Organization Historically, cemeteries were America’s first parks as they provided a manicured place for people to spend time together and picnic. The facility’s design was influenced by this and public space was added to the program.  Model The design of the structure allows for maximum sun exposure to light the interior because the building is off the grid. The seating area is created by a cut through the building allowing for visual access to the rest of the cemetery.  Design Students build a Parametric (BIM) model, combined with Rhino information to accurately reflect the design and the ability to extract material take offs, dimensions and other parametric information.  Construction Soils testing with students and a soils engineer.  Structural Components The structural components were modeled in Rhino and the data was used to drive digital fabrication processes such as CNC cutting and template design.  High tech fabrication All the structural steel was CNC plasma cut using the digital computer model of the structural design. The flat steel was slotted to improve ease of assembly and accuracy.  Prefabricating The slotted steel was welded by students in our metal shop and inspected by a structural engineer.  Components The steel components form the nodes or structural interface with the rest of the structure.  Foundation After two days of digging by hand, and not getting very far, larger equipment was brought in to speed up the process.  Foundation Students are tying, splicing and laying out a raft foundation. The idea is to have as little impact as possible.  Foundation Another reason for the shallow foundation is that for about 500 persons it is unclear where they are interred. This way we would not run into a possible encounter and having to delay the project by 3 weeks or more.  Foundation Students pouring concrete by using a line pump. Concrete trucks could not access the site so a 200 foot long line pump was used instead.  Foundation The raft slab after it is poured and finished.  Framing Prefabricated components ( structural bents ) are being assembled in place. These elements are treated LSL's that are prefabricated by students in the shops.  framing Not unlike barn raising the structure is being assembled over the course of 3 days  Framing The structural bays are clearly visible here and almost finished. Temporary bracing is used to create a stiff diaphragm before sheathing and steel goes on.  Siding Weathered steel siding is being installed over the structural bays. "Corten steel", is a group of steel alloys which were developed to eliminate the need for painting, and form a stable rust-like appearance if exposed to the weather for several years.  timelapse A collage of time-lapsed photo's taken to show the highlights of the process in one image. Prev Next Images and commentary of the design and construction process of the Columbia Cemetery Restoration and Storage Facility. Marcel managed and supervised a 12 week intense design build project done exclusively with undergraduate students of the University of Colorado ENVD Program / Architecture track. see also this link.

The project has won the 2012 City of Boulder Historic Preservation Award.

Students:

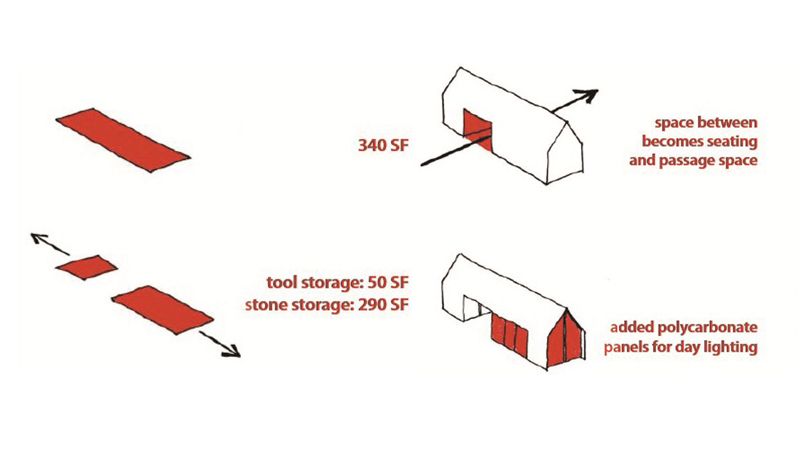

Scott Abernethy, Ian Carr, Nile Greenberg, Erin Masket, Andrew Mayer, Alex Mulhern, Taylor Odell, Preston Penny, Abe Rifkin, Jessica vanWey, Caleb White, Derek Woods

Assistant:

Mike Blea

Engineering:

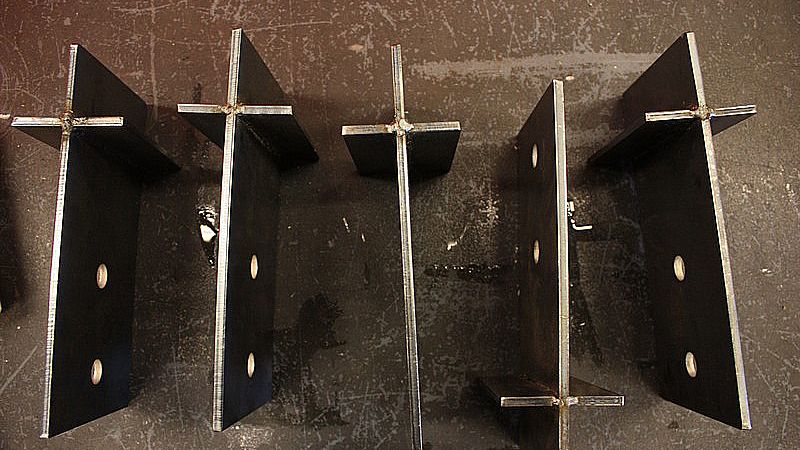

Studio NYL

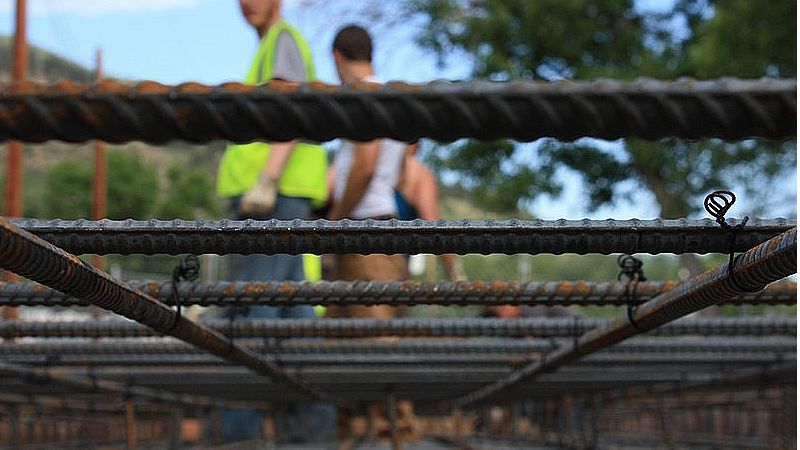

|